Search This Supplers Products:Vacuum FlangesVacuum FittingsVacuum bellowsVacuum ValvesVacuum Centering RingsVacuum Components

Stainless Steel CF Vacuum Bored Flange Nonrotatable for Vacuum Application

- group name

- CF Vacuum Flanges

- Min Order

- 1 piece

- brand name

- RUIJIA VACUUM COMPONENTS WHOLESALE MANUFACTURER

- Nearest port for product export

- Ningbo Port, Shanghai Port, Shenzhen Port, Tianjin Port

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, D/P D/A, MoneyGram, PayPal, Westem Union

- update time

- Tue, 12 Nov 2024 10:31:19 GMT

Paramtents

Product Name CF Vacuum bored flange Nonrotatable

Standard CF Standard

Seal material Viton,Silocone,Buna-N seal

Helium Leak Test 1×10 -9 Pa・m³/sec or less

Packging & Delivery

-

Min Order1 piece

Briefing

CF bored flanges,adopting a bayonet design, aligning the two flange buckles can complete installation anddisassembly.CF flanges size is from CF16-CF350 with the material of SS304/SS316.

Detailed

Stainless Steel CF Vacuum Bored Flange Nonrotatable for Vacuum Application feature

advantage

* CF flanges are available with tapped or untapped holes.

* A vacuum flange is a type of mechanical component that plays a crucial role in the construction of high-vacuum systems, particularly those used in the fields of physics, chemistry, and engineering research.

* Helium leakage test passed before shipping

* A plastic flange protective cap is included to avoid flange scratching during transportation

* CF vacuum flanges come in various sizes and shapes to accommodate different system configurations. Commonly, they feature a threaded or unthreaded design with standard or custom flange faces.

Stainless Steel CF Vacuum Bored Flange Nonrotatable for Vacuum Application specifications

| Product Name | CF Vacuum bored flange Nonrotatable |

| Brand | RUIJIA |

| Size | CF16,CF35,CF63,CF100,CF150,CF200,CF250,CF275,CF300,CF350 |

| Material | SS304, SS316L |

| Seal material | Oxygen free copper, silver plated copper |

| Standard | CF Standard |

| Temperature | -200~800℃ |

| Working Pressure | Vacuum~atmosphere pressure |

| Helium Leak Test | 1×10 -9 Pa・m³/sec or less |

| Packing | sealed plastic bag with a protective plastic cap. |

| CF Vacuum flange types | CF Vacuum bored flange nonrotatable,CF Vacuum bored flange nonrotatable-tapped bolt holes,CF Vacuum bored flange Rotatable,CF Vacuum bored flange rotatable-tapped bolt holes,CF Reducing flange |

Product parameters

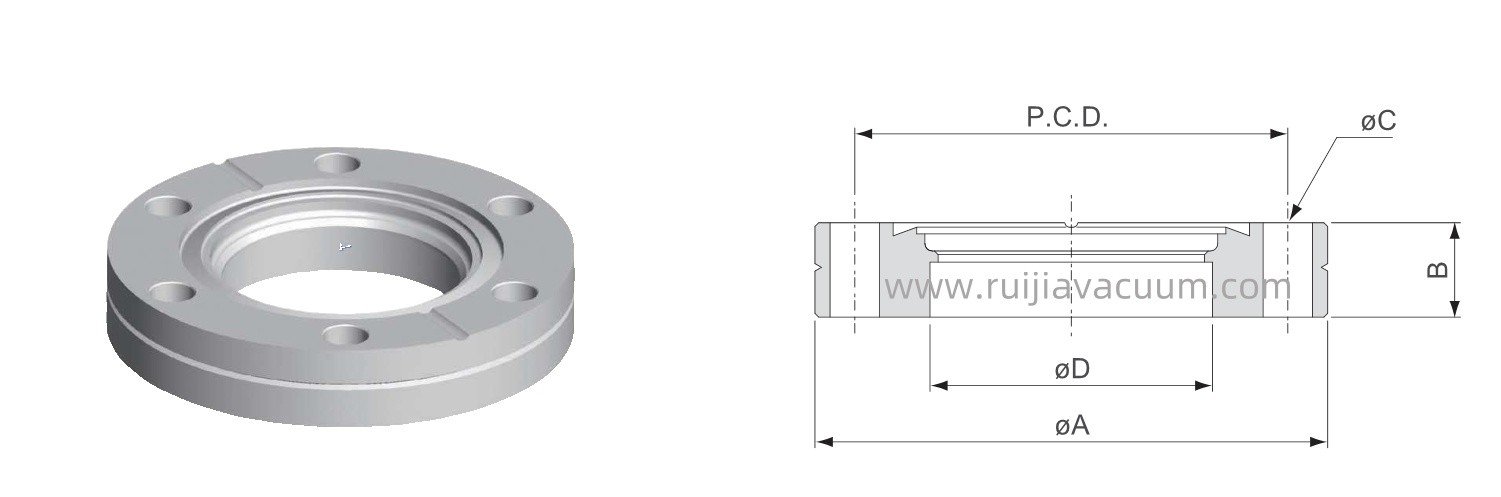

Stainless Steel CF Vacuum Bored Flange Nonrotatable for Vacuum Application Unit:mm

| Model No. | Material | A | B | C*NO | D | P.C.D |

| CF16B7 | S.S.304/316 | 33.8 | 7.5 | 4.4*6 | 6.5 | 26.9 |

| CF16B12 | S.S.304/316 | 33.8 | 7.5 | 4.4*6 | 12.9 | 26.9 |

| CF16B19 | S.S.304/316 | 33.8 | 7.5 | 4.4*6 | 19.15 | 26.9 |

| CF35B25 | S.S.304/316 | 69.5 | 12.7 | 6.7*6 | 25.6 | 58.7 |

| CF35B38 | S.S.304/316 | 69.5 | 12.7 | 6.7*6 | 38.3 | 58.7 |

| CF35B42 | S.S.304/316 | 69.5 | 12.7 | 6.7*6 | 42.9 | 58.7 |

| CF63B51 | S.S.304/316 | 113.6 | 19 | 8.4*8 | 51.1 | 92.1 |

| CF63B63 | S.S.304/316 | 113.6 | 19 | 8.4*8 | 63.7 | 92.1 |

| CF100B102 | S.S.304/316 | 151.6 | 21.5 | 8.4*16 | 102.2 | 130.3 |

| CF150B153 | S.S.304/316 | 202.5 | 24 | 8.4*20 | 153.1 | 181 |

| CF200B204 | S.S.304/316 | 253.2 | 24.7 | 8.4*24 | 203.7 | 231.8 |

| CF250B255 | S.S.304/316 | 304 | 28.5 | 8.4*32 | 255 | 284 |

| CF275B255 | S.S.304/316 | 336.5 | 28.5 | 10.3*30 | 255 | 306.5 |

| CF300B305 | S.S.304/316 | 355.6 | 28.5 | 10.3*30 | 305.4 | 325.7 |

| CF350B356 | S.S.304/316 | 419.1 | 28.5 | 10.3*36 | 356.1 | 388.9 |

Assembly Instructions for CF Flanges

1.Apply a small amount of high temperature anti-seize compound to the bolt threads.

2. Check that both flange surfaces are clean and sealing edges are free from nicks and scratches.

3. Using clean, lint free gloves, unpack gasket.

4. Place gasket in the knife edege counterbore of nonrotatable flange.

5. Align the mating hole pattern and leak test grooves.

6. Install the proper bolts and tighten had tight. Check to see that the flange faces are parallel.

7. Tighten the bolts 1/4 to 1/2 turns using a star pattern until the flange faces are metal to metal.

Production Center

Packing & Shipping

Application